How 3D Scanning Enhances BIM Integration

Wiki Article

Enhancing Manufacturing Processes: The Impact of 3D Laser Scanning on Quality Assurance

3D laser scanning modern technology is changing high quality control in manufacturing. By offering exact measurements and high-resolution information, it enables producers to recognize discrepancies from specifications with simplicity. This advancement not just simplifies examination processes however also enhances functional performance. 3D Scanning. The implementation of this modern technology comes with its own set of obstacles. Checking out these elements exposes the broader effects for sectors and the future landscape of manufacturing

Recognizing 3D Laser Scanning Innovation

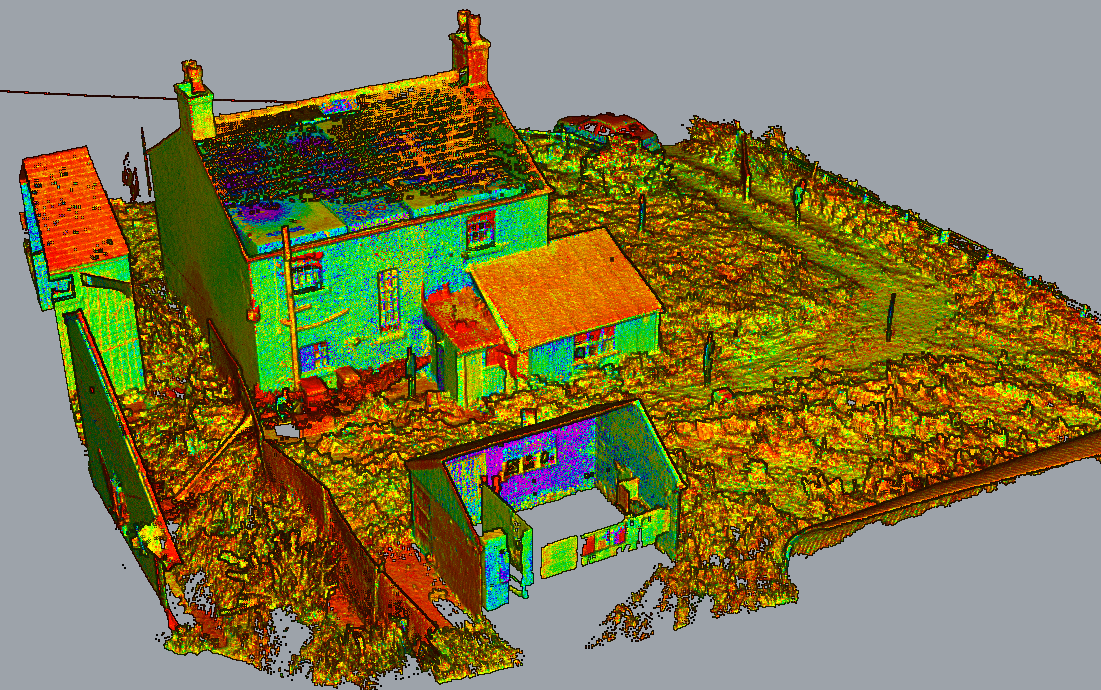

Although 3D laser scanning technology has progressed substantially in recent times, its fundamental concept stays simple: recording the exact geometry of items utilizing laser light beams. This innovation employs laser light to gauge distances in between the scanner and different points on an object's surface. The information collected is after that refined to develop a thorough 3D design, properly mirroring the measurements and contours of the scanned object.Typically, 3D laser scanners can be classified into two primary types: call and non-contact scanners. Contact scanners literally touch the challenge collect dimensions, whereas non-contact scanners use laser beam of lights to record information from a range. The versatility of this technology allows its application throughout various industries, consisting of architecture, construction, and manufacturing. Its ability to produce high-resolution models assists in top quality control, reverse design, and rapid prototyping, eventually enhancing layout accuracy and efficiency in production procedures.

Benefits of 3D Laser Scanning in Manufacturing

As manufacturers seek to boost performance and precision in their processes, the benefits of 3D laser scanning have actually come to be increasingly evident. This ingenious technology permits rapid and extremely accurate measurements of complicated geometries, substantially decreasing the time required for top quality checks. By catching comprehensive data, makers can recognize inconsistencies early in the production procedure, thus minimizing waste and revamp expenses.Moreover, 3D laser scanning promotes better style recognition, making it possible for engineers to contrast as-built conditions with original requirements. This capacity assures that any kind of deviations are promptly resolved, enhancing general product high quality. In enhancement, the technology sustains the development of electronic doubles, which can be made use of for simulations and process optimizations. Consequently, producers not only raise their functional effectiveness however likewise boost their affordable benefit out there. Overall, the integration of 3D laser scanning represents a transformative step towards accomplishing greater criteria in manufacturing quality assurance.

Combination of 3D Laser Scanning Into High Quality Control

Incorporating 3D laser scanning into top quality control procedures enhances the precision and performance of inspections throughout production. This technology enables manufacturers to record in-depth, high-resolution information of elements and assemblies, allowing for specific dimensions and contrasts against design specifications. By utilizing 3D laser scanning, organizations can identify variances from resistances more properly, which is important for keeping item integrity.

Real-World Applications and Instance Research Studies

Real-world applications of 3D laser scanning in manufacturing show its transformative effect throughout different industries. Aerospace firms use this innovation to carry out exact evaluations of components, ensuring they satisfy stringent safety and security requirements. A notable situation included a leading aircraft producer that employed 3D laser scanning to streamline its top quality control procedures, significantly minimizing assessment times and errors.In the automobile field, makers have actually applied laser scanning to develop digital doubles of their cars, making it possible for real-time adjustments during manufacturing. One vehicle firm reported a 30% decrease in rework expenses after incorporating this modern technology into their production line.

In the consumer goods sector, firms are making use of 3D laser scanning for rapid prototyping, allowing for quicker models and enhanced item styles. These applications highlight exactly how 3D laser scanning not only improves precision my review here but additionally enhances performance and development throughout numerous production domains.

Getting Over Challenges in Execution

Carrying out 3D laser scanning in producing presents a number of obstacles that organizations need to navigate to completely realize its benefits. One significant hurdle is the preliminary expense of equipment and software program, which can prevent firms from adopting this innovation. Additionally, integrating 3D laser scanning into existing process needs getting over resistance to transform among staff members, necessitating complete training programs to assure proficiency. Data administration likewise positions a difficulty, as the high quantity of information created by 3D scanning need to be effectively processed and assessed to derive workable insights. Furthermore, compatibility problems with legacy systems may prevent seamless integration, demanding possible upgrades or modifications. Attending to these difficulties is essential for producers intending to improve quality control and optimize production processes. By creating clear approaches for training, financial investment, and data monitoring, companies can alleviate these challenges and launch the transformative possibility of 3D laser scanning in their procedures.Future Patterns in 3D Laser Scanning for Manufacturing

As manufacturing remains to develop, the assimilation of 3D laser scanning with enhanced automation is anticipated to change manufacturing processes. Enhanced information analytics will play a vital role in maximizing process and enhancing quality assurance. These trends highlight the potential for higher performance and precision in producing atmospheres.

Enhanced Automation Integration

Although the combination of automation in manufacturing has been steady, the future of 3D laser scanning is positioned to accelerate this fad significantly. As manufacturing procedures become significantly complex, the need for precise, real-time measurements expands. 3D laser scanning technology provides automated data capture, lowering labor prices and decreasing human error. This combination over at this website allows producers to improve top quality control procedures, making it possible for fast discovery of variances in manufacturing. Furthermore, the alignment of 3D laser scanning with robotics and automated systems promotes smooth operations, enhancing general effectiveness. As producers take on these innovative innovations, they can anticipate enhanced precision and performance, placing themselves competitively in a swiftly progressing market. The harmony between automation and 3D laser scanning notes a substantial leap onward in producing technology.Improved Data Analytics

The combination of automation has led the way for improvements in data analytics within the domain name of 3D laser scanning. Manufacturers are progressively leveraging innovative formulas and device knowing methods to examine vast datasets generated by laser scans. This improved information analytics capacity enables real-time surveillance of producing procedures, enabling the recognition of problems and discrepancies better than typical techniques. Predictive analytics can visualize prospective problems, significantly reducing downtime and improving general efficiency. Additionally, the capacity to visualize information in 3 measurements provides deeper understandings right into production process, promoting far better decision-making. As 3D laser scanning technology proceeds to advance, the role of data analytics will end up being progressively important in driving technology and keeping affordable benefit in production.Frequently Asked Concerns

What Industries Advantage one of the most From 3D Laser Scanning?

The industries that benefit most from 3D laser scanning include production, building, aerospace, vehicle, and healthcare. These fields make use of the technology for precision measurements, quality guarantee, and effective design procedures, considerably enhancing general operational effectiveness.Exactly How Does 3D Laser Scanning Contrast to Traditional Measurement Approaches?

3D laser scanning offers greater precision and rate compared to standard measurement methods. It records thorough geometries promptly, reducing human mistake and facilitating better analysis, which inevitably improves overall quality assurance in numerous sectors.What Is the Expense of Applying 3D Laser Scanning Technology?

The expense of applying 3D laser scanning modern technology varies significantly, usually ranging from see this website $10,000 to $100,000, relying on training, software, and tools. Organizations should consider these expenditures versus prospective performance and top quality enhancements.Exist Details Software Program Demands for 3D Laser Scanning?

Yes, 3D laser scanning needs specific software, including information processing and modeling applications. Typical options include CAD software program, point cloud processing devices, and specialized applications that help with the assimilation and analysis of scanned data for perfect outcomes.How much time Does a Common 3D Laser Scanning Refine Take?

A common 3D laser scanning procedure can take anywhere from a couple of minutes to a number of hours, relying on elements like the size of the object, complexity of the atmosphere, and required degree of detail for accuracy.3D laser scanning innovation is changing quality control in production. 3D laser scanning technology has advanced substantially in recent years, its basic concept remains simple: capturing the precise geometry of items making use of laser beam of lights. Integrating 3D laser scanning right into quality control procedures boosts the accuracy and effectiveness of assessments throughout production (3D Scanning). 3D laser scanning innovation uses automated information capture, minimizing labor expenses and decreasing human error. The expense of applying 3D laser scanning innovation differs substantially, usually ranging from $10,000 to $100,000, depending on training, devices, and software program

Report this wiki page